Technology

Our machine is capable of 2D and 3D design. Complex components are easily manufactured through the direct import of files from most CAD systems for precision machining. We have 6 high end 3 axis machining centres, 2 CNC routers and 5 axis machining centres.

We produce machined components with a high degree of consistency to close tolerances with no burrs. Surface finishes can be optical-quality grade as needed via plastic polishing.

Machining centre table size X700 Y400 Z200mm

CNC router table size X4000 Y2000 Z200mm

5 axis machining centre

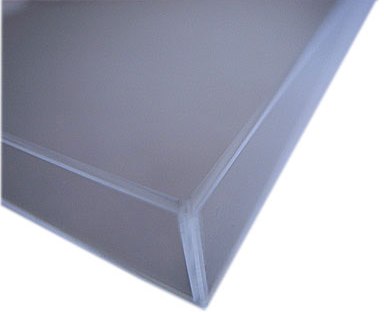

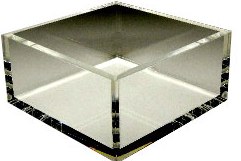

Polymerizing acrylic cements can be used to produce strong, optically clear joints without any air bubbles that are cosmetically attractive. The jointing can be done by butt or mitered style. It is also to possible to laminate two sheets surfaces.

Solvent bonded joint is glueing two thin acrylic sheets which are less than 15mm thick to each other. Solvent adhesives soften the acrylic surface and then diffuse and evaporate, allowing the parts to harden together. The jointing can be done by butt or mitred style.

Digital UV printer

CO2 laser

CO2 laser

It is possible to cut acrylic of 10mm or less. Laser cutting creates a beautifully finished, clean edge on plastics. It does not leave an inside radius like the CNC router.

Heat forming

We have strip heaters, Infrared heaters, and air oven heaters. We are capable of sharp radius bending for up to 5mm plastic sheets. We provide big radius bending by using infrared heaters for acrylic sheets up to 50mm thickness. We can also do molding and draping by using air oven heaters.

Diamond polisher

Factory over view